To ensure product quality and its survival from factory to port to across the ocean, carton strength is a vital consideration. A carton drop test is a procedure used to verify your carton can protect the products inside when being dropped multiple times and from different angles.

Accepted International Standards for Drop Tests: ISTA 1A

The International Safe Transit Association (ISTA) is “an organization focused on the specific concerns of transport packaging.” ISTA 1A, a protocol developed by them, outlines the acceptable procedures for several tests, including vertical shock tests, alternative incline tests, and alternative horizontal tests. Here are 5 points to note:

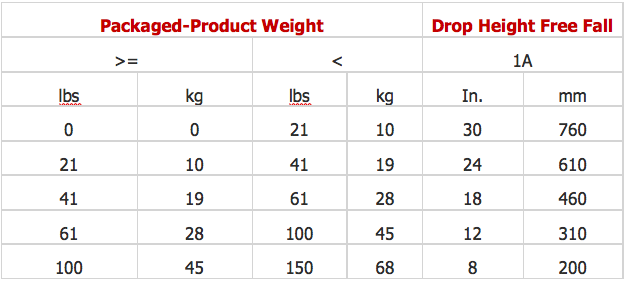

1. Drop Test Height is Determined by Carton Weight

Curious about the height an inspector should drop the carton from during a product inspection? Take a look at below table:

To illustrate,

- A carton weighing less than 21 lbs (10 kg) would be dropped from a height of 30 inches (760 mm)

- A carton weighing between 100 lbs (45 kg) and 150 lbs (68 kg) should be dropped from a height of 8 inches (200 mm).

2. Cartons are Dropped 10 Times During Testing

When performing a drop test, the carton is dropped on its most fragile corner, 3 of its edges, and 6 of its faces. Below diagram identifies these areas:

In fact, there’s a specific sequence to drop the carton! See below:

3. Open Your Carton to Determine a Pass or Fail Result

After the drop test, open your carton for inspection. If any of the following is found, the carton fails the test:

- Damage to the export carton

- Damage to the product packages inside

- Scratches, dents, or other damage to products

- The products are not functioning as expected

4. Burst Strength is Key to a Pass

Burst strength is a measure of a box’s resistance to rupturing. It is measured in Pounds per Square Inch (PSI). Master cartons should have a seal specifying the burst strength and carton manufacturer, generally on the bottom side of the carton.

Generally, a burst strength of 200 PSI is sufficient to pass the standard drop test.

5. ISTA 1A Outlines Even More!

While drop tests are fairly common, ISTA 1A also covers vertical shock tests, alternative incline tests, and alternative horizontal tests, which are not done by the average importers. These require the use of specialized equipment such as a shock test machine, incline impact tester and horizontal impact test system.

It is highly recommended to include the carton drop test as part of your pre-shipment inspection.

This article was originally published on the Insight Quality Services website.

Andy Church – Founder & CEO of Insight Quality Services

Andy Church has over 20 years of experience in product quality and founded his company in 2014. Insight Quality provides product inspections, factory audits, lab testing, and other services in 17 countries worldwide.

At hktdc.com Sourcing, we highly value supplier qualities and ensure products are in compliance with the standards above. Start your sourcing journey by clicking through below banners: