Before your manufacturer begins production, they may need raw materials such as a specific grade of plastic or metal. If proper procedures aren’t in place to ensure raw material quality, the end product and business outcomes may suffer.

Substandard materials can make your products more prone to breakage or perform inadequately, leading to problems later on, such as increased returns, poor reviews, and customer complaints.

Learn More:

What is Quality Fade, and How Can You Avoid It?

What practices should your manufacturer follow when inspecting raw materials? Read this article to find out the essential checklist for quality assurance.

How Should Your Manufacturer Handle Incoming Materials?

Any factory you work with should have a well-defined Quality Management System. ASQ defines this as “A structured framework that defines and documents an organization’s processes, procedures, and responsibilities for achieving quality policies, practices, and objectives.”

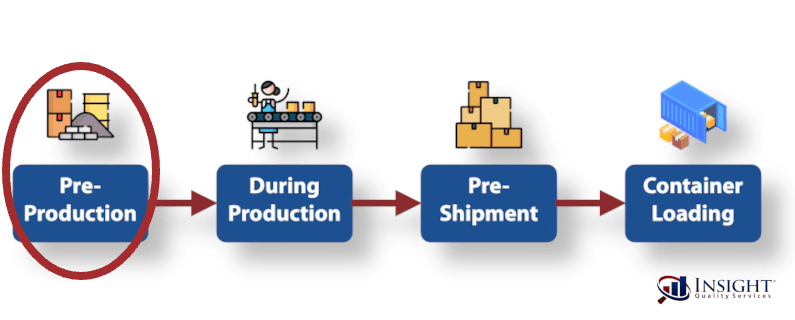

With a QMS in place, they should be able to give you a step-by-step overview of their incoming material inspection procedure. Conducting raw material inspections typically involves four steps.

Step 1: Keep All New, Untested Material in a Separate Area

When they order a batch of raw materials and receive a shipment—whether it’s 304 stainless steel, 6061 aluminum, PET plastic, or something else—they should set the incoming raw materials aside in a specified area.

Step 2: Conduct a Receiving Inspection to Test Raw Material

The manufacturer should check the material in the receiving area to ensure it meets the specified requirements.

Step 3: Reject Any Material That Does Not Match Specifications

If the material does not meet specifications, it should be rejected. After discovering any non-conforming material, the inspector should set it aside and store it before sending it back. They should then follow up with the supplier to discuss the quality issues and determine the appropriate corrective action.

Step 4: Move Accepted Material to Pre-Production Storage

If a batch of material has been inspected and meets the specified criteria, the inspector can remove it from the receiving area. Then, they should send it to the pre-production storage area, where it can be used later for the manufacturing process.

3 Tips to Ensure Quality of Raw Materials

Verifying material quality can be tricky when working with a factory overseas. Here are some actions you can take to help ensure your manufacturer faithfully adheres to good practices and will provide the quality you expect.

1) Provide Material Specifications to the Factory

You can’t expect your supplier to use a specific steel grade or type of plastic unless you provide precise specifications. A lack of specifications is one of the major reasons importers need to scrap and rework products.

Provide your factory with product specifications that include all relevant details about your item, such as its size, shape, measurements, and colors—and its material and component details.

2) Regularly Audit Your Supplier’s Quality System

Factory audits are essential when you’re considering a new supplier or have issues with an existing one and want to understand the problem better. They review the documented processes for raw material quality control and check the factory’s receiving inspection records to verify that they’ve consistently followed them.

3) Conduct Lab Tests on High-Risk Raw Materials

Lab testing is essential for verifying safety, regulatory compliance, and product performance. You might be subject to various regulations depending on your product’s category.

For example, if you sell products in the US, you may need a General Certificate of Conformity (GCC) or Children’s Product Certificate (CPC). If you are selling products in California, they may need to comply with Cal Prop 65. Testing raw materials helps verify compliance with these requirements.

Not every batch of raw materials needs to be lab tested, but some are at higher risk than others and may warrant more frequent testing. For example, incoming paint should be tested to ensure it is lead-free. Fabric should be tested to confirm it meets flammability and colorfastness standards.

You can ask your supplier to provide a testing certificate for each batch to ensure they have verified its compliance. You can also periodically conduct your own tests with a testing lab to reduce the risk that comes from relying only on the supplier to authenticate their goods.

This article was originally published on the Insight Quality Services website.

Andy Church – Founder & CEO of Insight Quality Services

Andy Church has over 20 years of experience in product quality and founded his company in 2014. Insight Quality provides product inspections, factory audits, lab testing, and other services in 17 countries worldwide.

Be sure to look for a trusted e-Marketplace such as hktdc.com Sourcing that safeguards product quality to the highest standards. Start searching for quality products by clicking the banner below:

Incoming Materials Inspection FAQ

1. What is incoming materials inspection?

Incoming materials inspection is the process of checking raw materials (e.g., metals, plastics, textiles) after they arrive at the factory but before they are used in production. The goal is to ensure they meet specifications, are free from defects, and won’t compromise final product quality.

2. Do all raw materials need lab testing?

Not always. Routine lab tests may be unnecessary for low-risk materials, but items like paint, textiles, or plastics often need testing for regulatory compliance (e.g., lead-free certification, flammability tests).

3. Why is incoming materials inspection important?

If raw materials are substandard, the finished goods may break easily, fail performance tests, or not comply with regulations. This can lead to higher returns, bad reviews, and reputational damage. A proper system helps avoid these risks early.